Modified plastics are indeed effective in protecting the bottle and the system during the filling process. The use of modified plastics with good sliding properties can reduce the friction between the bottle and the filling machine, reduce scratches and wear, and thus prolong the service life of the system.

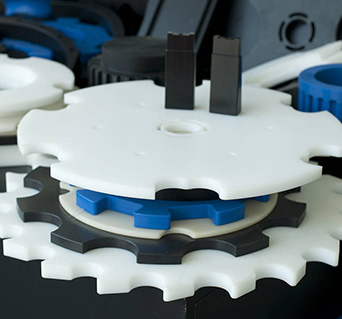

Compounded plastics play an important role in beverage, food and other filling machines. The sliding properties and wear resistance of the material are key requirements. Our product line covers the best materials for every application, whether antistatic properties, antimicrobial properties, or high temperature cleaning are required.

Our modified plastic materials have excellent sliding properties, which reduce the friction of the bottle during the filling process, reducing the possibility of sticking and jamming. At the same time, they are also wear-resistant and can resist wear caused by long-term operation and high-speed friction.

In addition, our modified plastic materials also have other excellent properties, such as antistatic performance, antibacterial performance and high temperature cleaning performance. These properties make our materials ideal for filling systems, protecting systems and ensuring product quality and safety.

If you have any further needs or questions about modified plastic materials, please feel free to contact us. Our professional team will be happy to provide you with support and solutions to meet your

Website: https://www.uhmwpes.com

Alibaba: https://hnaycg.en.alibaba.com

Facebook: https://www.facebook.com/AYCGCO

YouTube:https://www.youtube.com/channel

720° panorama:https://720yun.com/t/1cvkbq7qr1e#scene_id=93390397

AnYang Ultrahigh Industrial Technical Co.,Ltd.

Address: YiGou New Manufacturing Park,Anyang,Henan,China