Bulk and mining industry

Reduce cleaning work by optimizing material flow

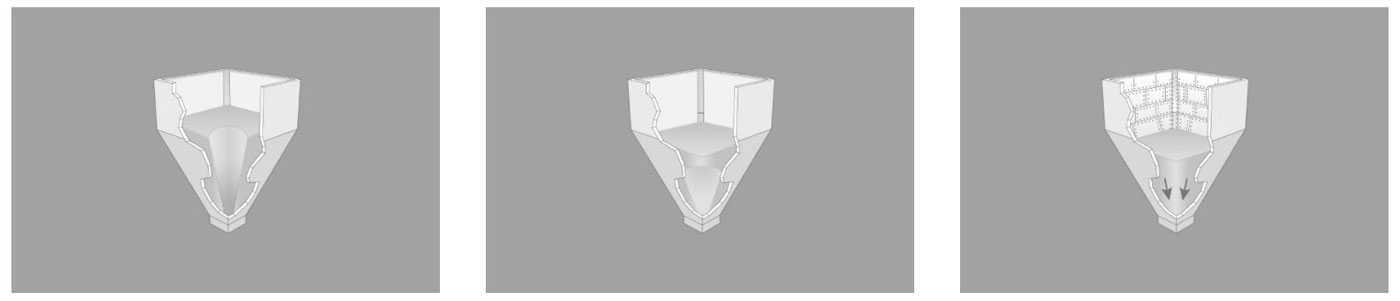

Many areas of industrial production use large amounts of raw materials, which are stored as bulk goods in silos or silos. Highly abrasive materials such as sand, coal or ore in the bulk material handling area can cause serious damage. Linings made of different materials-tailored to the respective bulk material-protect and optimize the sliding process in their application. The correct lining prevents sticking to the silo wall and bridging when the material flows out. Our comprehensive product range provides you with suitable materials for various applications.

But which lining material is most suitable (for example, sticky or hard-to-leak bulk cargo)? A long-term partner of Murdotec provided his customers with our tried-and-tested PE-UHMW lining plastic Dialen® and achieved outstanding results in the long term. The following is his experience report:

“In a coal mine in Borneo, Indonesia, we provided our customers with 20 mm thick Dialen® panels.

Application-Coal Mine Transport Shaft

The material passing through the conveyor belt is the coal deposit from the soil-covered container, which is processed in the filter press, so the water content is very low. Coal materials are now almost solid.

The material being conveyed is wet and sticky. When it hits the Dialen® lining in the conveying shaft, the impact wear will be significantly reduced, and the adhesion of the conveyed coal will be minimized.

By using Dialen® linings, huge improvements can be achieved, which are reflected in reduced energy costs, reduced downtime, and reduced conveyor maintenance.

The machine can run for a long time without failure without interrupting the feeding. Overall, the customer is very satisfied and pleased that he can use Murdotec’s Dialen® to solve the accumulation problem and operate the machine more efficiently. “