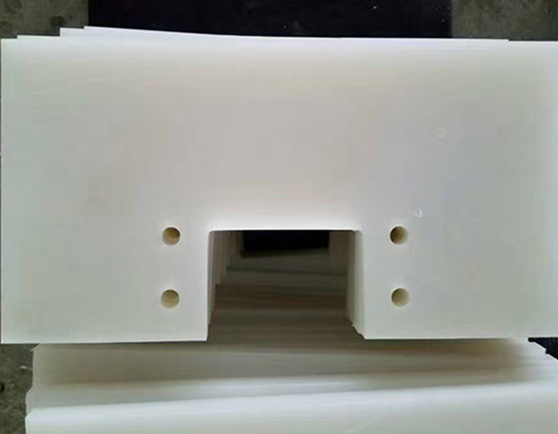

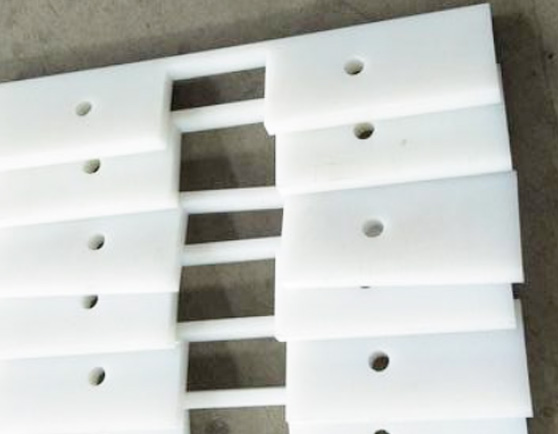

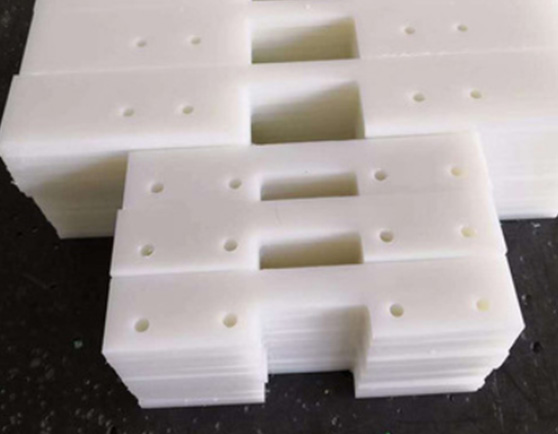

The mechanical properties are higher than those of general high-density polyethylene. Outstanding impact resistance, stress cracking resistance, high temperature creep resistance, low coefficient of friction, self-lubrication, excellent chemical resistance, fatigue resistance, noise damping, nuclear radiation resistance, etc. The scraper product is made of ultra-high molecular weight polyethylene (UHMWPE) due to its extremely high melt viscosity, it is not liquid even when heated to its crystalline melting point, and this immobility is due to its ultra-long single molecule The chain is highly tangled. In layman’s terms, it is like a pile of hemp ropes. Low molecular weight polyethylene such as polyethylene wax is like 10,000 one-meter-long hemp ropes that are entangled together and can be easily separated; ordinary polyethylene products are like a thousand ten-meter ropes. The long hemp ropes are entangled together, and it is not easy to separate them, but they can be separated with a little effort; and ultra-high molecular weight polyethylene (UHMWPE) is like a hundred hemp ropes 100 meters long. Together, it can be difficult to separate them even with a lot of effort. Because of this, ultra-high molecular weight polyethylene (UHMWPE) has many extraordinary properties. Scraper blade trye: Primary Belt Scraper The primary belt scraper, also known as primary belt cleaner, scrapes or cleans residual material from belting, rollers and other surfaces, and is suitable when sticky and moist or coarse material is transported. Secondary Belt Cleaner The secondary belt cleaner removes excess material that the primary belt cleaner leaves on the belt. Usually used together with a primary belt scraper for best results, secondary belt cleaners can also be used on their own if the transported material is fine and dry. Scraper blade key benefits: chemical resistance; high temperature resistance; durability – Fewer blade replacements are necessary; resistance to abrasion; non-toxic;.

The mechanical properties are higher than those of general high-density polyethylene. Outstanding impact resistance, stress cracking resistance, high temperature creep resistance, low coefficient of friction, self-lubrication, excellent chemical resistance, fatigue resistance, noise damping, nuclear radiation resistance, etc. The scraper product is made of ultra-high molecular weight polyethylene (UHMWPE) due to its extremely high melt viscosity, it is not liquid even when heated to its crystalline melting point, and this immobility is due to its ultra-long single molecule The chain is highly tangled. In layman's terms, it is like a pile of hemp ropes. Low molecular weight polyethylene such as polyethylene wax is like 10,000 one-meter-long hemp ropes that are entangled together and can be easily separated; ordinary polyethylene products are like a thousand ten-meter ropes. The long hemp ropes are entangled together, and it is not easy to separate them, but they can be separated with a little effort; and ultra-high molecular weight polyethylene (UHMWPE) is like a hundred hemp ropes 100 meters long. Together, it can be difficult to separate them even with a lot of effort. Because of this, ultra-high molecular weight polyethylene (UHMWPE) has many extraordinary properties. Scraper blade trye: Primary Belt Scraper The primary belt scraper, also known as primary belt cleaner, scrapes or cleans residual material from belting, rollers and other surfaces, and is suitable when sticky and moist or coarse material is transported. Secondary Belt Cleaner The secondary belt cleaner removes excess material that the primary belt cleaner leaves on the belt. Usually used together with a primary belt scraper for best results, secondary belt cleaners can also be used on their own if the transported material is fine and dry. Scraper blade key benefits: chemical resistance; high temperature resistance; durability – Fewer blade replacements are necessary; resistance to abrasion; non-toxic;

Scraper blade trye:

Primary Belt Scraper

The primary belt scraper, also known as primary belt cleaner, scrapes or cleans residual material from belting, rollers and other surfaces, and is suitable when sticky and moist or coarse material is transported.

Secondary Belt Cleaner

The secondary belt cleaner removes excess material that the primary belt cleaner leaves on the belt. Usually used together with a primary belt scraper for best results, secondary belt cleaners can also be used on their own if the transported material is fine and dry.

Scraper blade key benefits:

chemical resistance;

high temperature resistance;

durability – Fewer blade replacements are necessary;

resistance to abrasion;

non-toxic;

low coefficient of friction; and color-coded.